Custom Option |

Available Options |

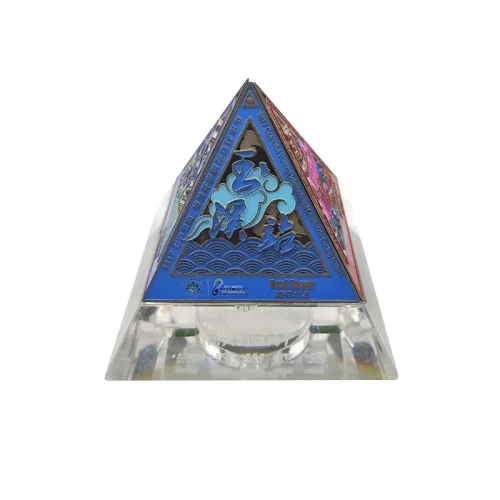

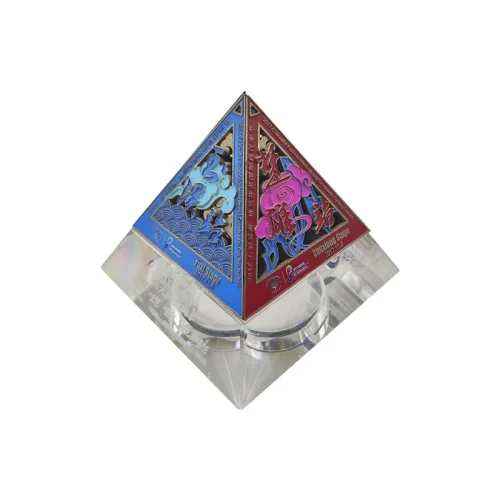

| Material | Zinc Alloy / Brass, Iron / Wooden / Acrylic / Dual Material |

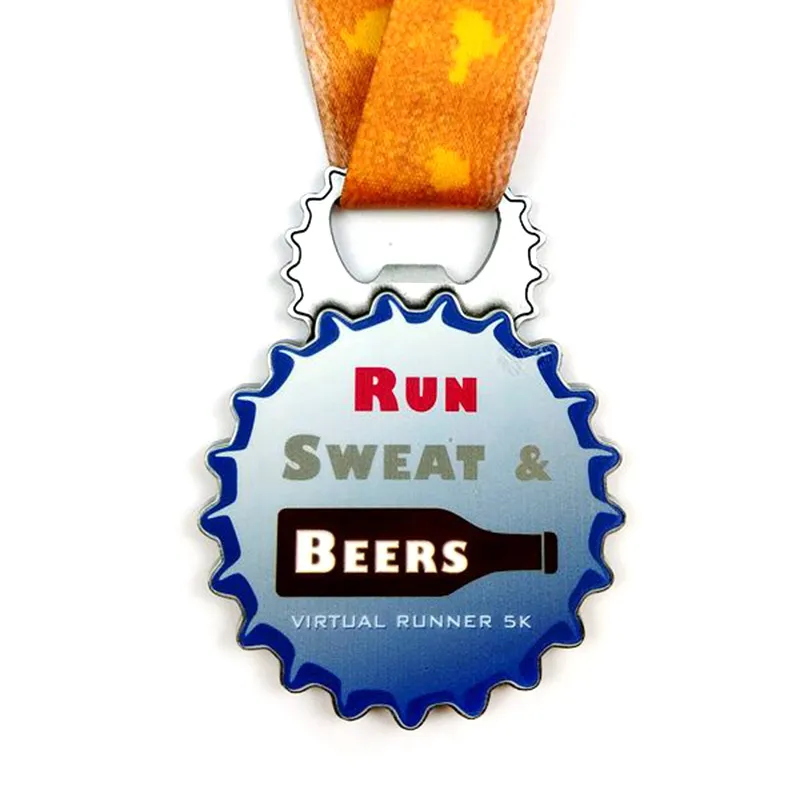

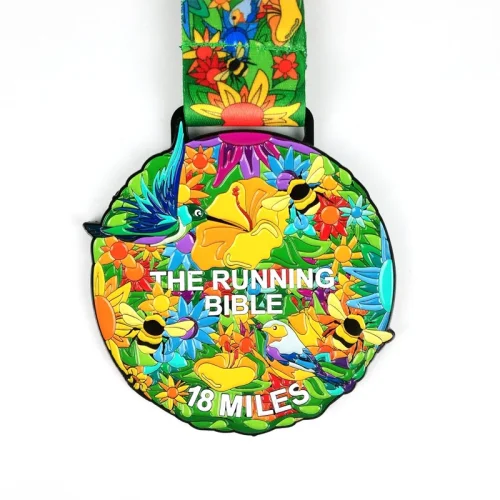

| Type | One Side with Design / Both Sides with Design / Three-dimensional Multilateral Design |

| Style | Soft Enamel / Hard Enamel / Translucent Enamel / Paper Sticker / Die Struck / Offset Printing / Offset Printing with Epoxy Coating / Soft Enamel with Epoxy Coating / Soft Enamel with Glitter / Soft Enamel with Glowing / Soft Enamel with Printing |

| Medal Material Color/Finish | Shiny Gold / Shiny Silver / Shiny Copper / Shiny Rose Gold / Shiny Brass / Black Nickel / Satin Gold / Satin Silver / Satin Copper / Satin Brass / Satin Black Nickel / Antique Gold / Antique Silver / Antique Brass / Antique Copper / Spray Gold / Spray Silver / Brushed Brass / Dual Plating |

| Material Colors | Single Metal Color / Two Metal Colors |

| Number of Colors in Design | No Color / 1-5 Colors / 6-8 Colors / 9-10 Colors / 11-13 Colors / 14-15 Colors / 16-17 Colors / 18-20 Colors / 21+ Colors / Unlimited Colors-Printed Design |

| Medal Ribbon Width | 0.75 / 1 / 1.25 / 1.5 / 1.75 Inches |

| Medal Ribbon Length | 14.5 / 15 / 15.5 / 16 / 16.5 / 17 / 18 Inches |

| Medal Ribbon Loop Type | Round Shape / Arc Shape / Semi-closed Shape / Wide Shape – Custom Fit / Wide Shape – Large / Built-in Ribbon Holes / Back Shape / Custom Shape |

| Engraving | Sequential Names / Sequential Numbers / Custom Words |

| Packaging and Branding | Clear Poly Bag / Velvet Pouch / Velvet Box / Arcylic Box / Suspension Box / Wooden Box / Hard Paper Box |

Medals are iconic decorations that symbolize honor and achievement, and are often used to recognize individuals or groups that have excelled in a particular field. Medals have a rich historical tradition and are considered an important form of recognition. In modern times, medals are important gifts and awards.

Manufacturing Process of Lacquered Medals

Our lacquered medals are precisely crafted by skilled artisans and modern equipment to ensure top quality products. Here is an overview of our manufacturing process:

Design and mold making

Our process begins with creativity and design. Our team creates a detailed design based on the customer’s requirements. Once finalized, we create precise molds to accurately capture the details and contours of the design.

Material Sourcing

We use high quality metal materials such as zinc alloy, iron or stainless steel as the base material for our badges. These materials have excellent oxidation resistance and durability, making them ideal for creating beautifully lacquered medals.

Die casting and molding

Advanced stamping technology is used to cut the metal into badge shapes, which are then molded and finished to ensure consistent appearance and size.

Grinding and Polishing

Each badge is meticulously ground and polished to achieve a smooth, flawless surface ready for lacquering.

Varnishing

We apply a high quality lacquer to the medals through precise color matching and detailing. After lacquering, the medals are painted with vibrant colors and realistic designs that show the intended motifs and text.

Drying and Quality Inspection

After painting, the medals are baked and dried to ensure durability. Strict quality checks are carried out to ensure that each medal meets our standards and customers’ expectations.

Packaging and Delivery

Finally, each medal is carefully packaged to prevent damage during transportation. We offer flexible delivery options to ensure safe and timely delivery to our customers.

We are committed to providing outstanding lacquered medals and maintain strict quality control at every step of the process to ensure that our products meet the highest standards of appearance and performance. Please feel free to contact us with any questions or specific requests regarding our manufacturing process or services. We will be happy to provide you with customized support and assistance.