Creating shiny silver awards, such as custom silver medals, involves a meticulous manufacturing process to ensure they exhibit both high quality and aesthetic appeal. Here’s a detailed description of the process:

Manufacturing Shiny Silver Awards

Design and Prototyping

The first step in manufacturing silver awards is the design phase. Clients often provide specific requirements for custom silver medals, including size, shape, engraving details, and additional features such as logos or inscriptions. Designers use CAD (Computer-Aided Design) software to create precise digital models of the awards. These models are then used to produce prototypes, which allow clients to visualize the final product and make any necessary adjustments before mass production.

Material Selection

High-quality materials are essential for creating durable and visually appealing silver awards. Typically, these awards are made from sterling silver, which consists of 92.5% silver and 7.5% other metals (usually copper) to enhance strength and durability. For more cost-effective options, manufacturers may use silver-plated metals, which involve a base metal coated with a thin layer of silver.

Casting and Molding

Once the design is finalized, the production process begins with casting. The chosen metal is melted and poured into molds shaped according to the design. This step is crucial for forming the basic structure of the custom silver medals. Advanced techniques such as die-casting can be used for more intricate designs, ensuring high precision and consistency across all units.

Polishing and Plating

After the casting, the medals undergo several stages of polishing to achieve their signature shine. This process involves using various abrasives and polishing compounds to smooth the surface and enhance its reflective properties. For silver-plated awards, the next step is electroplating, where a thin layer of silver is deposited onto the surface of the base metal through an electrochemical process. This gives the medals a high-quality finish that resembles solid silver.

Engraving and Finishing

The engraved details, such as names, dates, and logos, are added using advanced engraving machines or laser engraving techniques. This step personalizes the custom silver medals and adds to their uniqueness and value. After engraving, the medals undergo a final round of polishing to ensure all surfaces are pristine and shiny.

Quality Control and Packaging

Each silver award is subjected to stringent quality control measures to ensure it meets the required standards. Inspections check for any imperfections in the metal, plating, or engraving. Once approved, the silver awards are carefully packaged to prevent any damage during transportation. Custom packaging options, such as velvet-lined boxes, can enhance the presentation and protect the medals.

The production of custom silver medals is a detailed and meticulous process that combines artistic design with advanced manufacturing techniques. From the initial design to the final polish, each step is crucial in creating stunning, high-quality silver awards that are cherished by recipients. Whether for sporting events, corporate achievements, or special recognitions, these awards symbolize excellence and accomplishment.

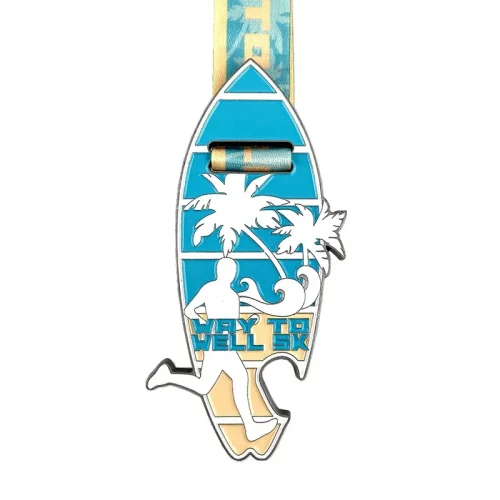

Products Details

Custom Option |

Available Options |

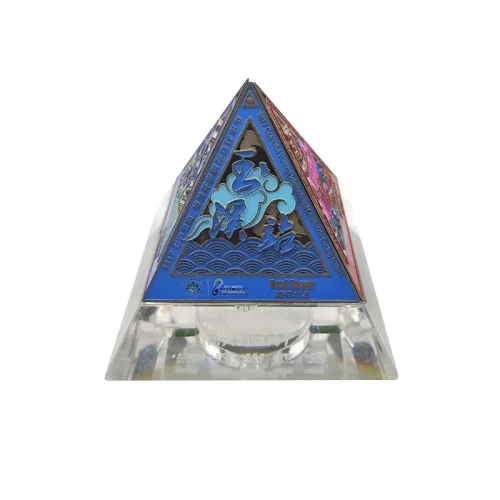

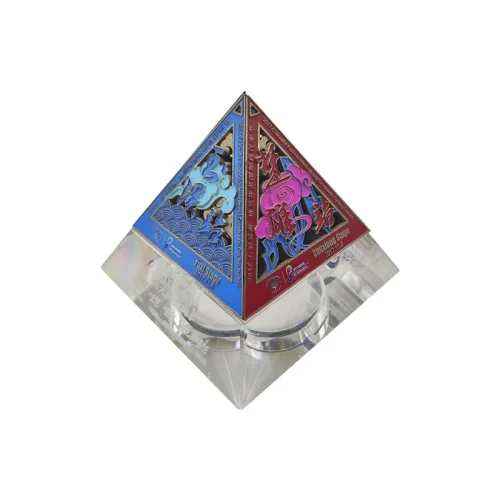

| Material | Zinc Alloy / Brass, Iron / Wooden / Acrylic / Dual Material |

| Type | One Side with Design / Both Sides with Design / Three-dimensional Multilateral Design |

| Style | Soft Enamel / Hard Enamel / Translucent Enamel / Paper Sticker / Die Struck / Offset Printing / Offset Printing with Epoxy Coating / Soft Enamel with Epoxy Coating / Soft Enamel with Glitter / Soft Enamel with Glowing / Soft Enamel with Printing |

| Medal Material Color/Finish | Shiny Gold / Shiny Silver / Shiny Copper / Shiny Rose Gold / Shiny Brass / Black Nickel / Satin Gold / Satin Silver / Satin Copper / Satin Brass / Satin Black Nickel / Antique Gold / Antique Silver / Antique Brass / Antique Copper / Spray Gold / Spray Silver / Brushed Brass / Dual Plating |

| Material Colors | Single Metal Color / Two Metal Colors |

| Number of Colors in Design | No Color / 1-5 Colors / 6-8 Colors / 9-10 Colors / 11-13 Colors / 14-15 Colors / 16-17 Colors / 18-20 Colors / 21+ Colors / Unlimited Colors-Printed Design |

| Medal Ribbon Width | 0.75 / 1 / 1.25 / 1.5 / 1.75 Inches |

| Medal Ribbon Length | 14.5 / 15 / 15.5 / 16 / 16.5 / 17 / 18 Inches |

| Medal Ribbon Loop Type | Round Shape / Arc Shape / Semi-closed Shape / Wide Shape – Custom Fit / Wide Shape – Large / Built-in Ribbon Holes / Back Shape / Custom Shape |

| Engraving | Sequential Names / Sequential Numbers / Custom Words |

| Packaging and Branding | Clear Poly Bag / Velvet Pouch / Velvet Box / Arcylic Box / Suspension Box / Wooden Box / Hard Paper Box |