Le choix de la bonne finition de placage est une étape fondamentale dans la conception de médailles personnalisées. Au-delà de l'esthétique, la finition influe sur la durabilité de la médaille, sur son toucher et même sur son adéquation avec le thème d'un événement ou d'une marque. Qu'il s'agisse de créer une impression durable ou de s'assurer que la médaille résiste à l'épreuve du temps, le choix d'une finition appropriée est essentiel. Ce guide présente les finitions les plus populaires, les éléments clés à prendre en compte et les moyens de garantir la qualité, afin de vous aider à faire le meilleur choix pour vos médailles personnalisées.

Comprendre le rôle du placage dans les médailles personnalisées

Pourquoi la finition du placage est-elle importante pour les médailles personnalisées ?

La finition du placage n'est pas seulement une couche décorative, c'est un élément déterminant du caractère de la médaille. Elle a un impact direct sur l'aspect, la sensation et l'usure de la médaille au fil du temps. Une finition idéale peut renforcer l'esprit de l'événement, en lui conférant un sentiment d'importance et de professionnalisme. La bonne finition peut permettre à votre médaille de se démarquer en rehaussant sa beauté et en lui offrant une protection accrue, ce qui lui permettra de conserver son éclat pendant de nombreuses années.

Types de matériaux couramment utilisés pour les médailles personnalisées

Les matériaux de base sont déterminants dans le choix d'une finition de placage. Médailles personnalisées utilisent généralement des métaux tels que l'alliage de zinc, le laiton, le fer ou l'acier inoxydable, chacun offrant des qualités uniques. L'alliage de zinc, par exemple, est polyvalent et se marie bien avec la plupart des finitions, tandis que le laiton offre un ton riche et chaud qui s'harmonise avec les finitions anciennes. Comprendre ces matériaux de base vous permet de choisir en connaissance de cause des finitions compatibles qui optimisent l'apparence et la durabilité.

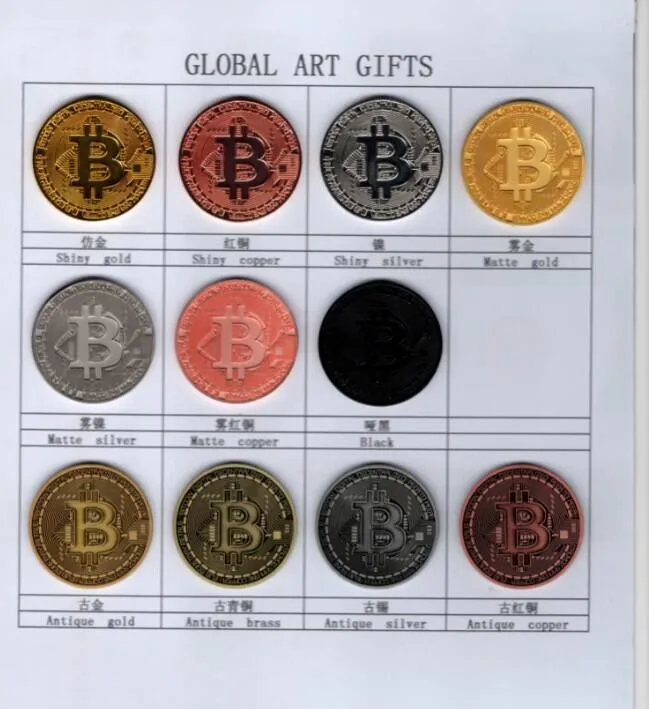

Finitions de placage populaires pour les médailles personnalisées

Placage d'or pour les médailles personnalisées

L'attrait esthétique: Les médailles plaquées or sont connues pour leur aspect brillant et luxueux. Elles sont souvent associées au prestige, ce qui en fait un choix populaire pour les récompenses de haut rang ou les pièces commémoratives.

Cas d'utilisation idéaux: Le placage d'or convient parfaitement aux récompenses synonymes d'excellence et d'honneur, telles que les médailles de tournoi, les récompenses d'entreprise ou les pièces de cérémonie. Il confère une élégance classique qui communique l'importance et la valeur.

Placage argenté pour un aspect professionnel

Appel élégant: L'argent a un ton poli et élégant qui donne aux médailles un aspect professionnel et intemporel. Les médailles plaquées argent conviennent à différents thèmes, des événements sportifs aux récompenses industrielles.

Praticité et polyvalence: L'argent est généralement choisi pour son équilibre entre luxe et rentabilité, ce qui en fait la solution idéale pour les récompenses sportives, les récompenses d'entreprise et les récompenses liées à des réalisations qui doivent avoir un aspect haut de gamme sans dépasser les limites du budget.

Des finitions antiques pour un look intemporel

Or, argent et bronze antiques: Les finitions antiques donnent de la profondeur et un aspect vintage aux médailles, leur conférant un sens de l'histoire et du caractère. Ces finitions sont idéales pour les créations de style classique ou rétro.

Avantages en matière de durabilité: Les finitions antiques sont généralement plus résistantes aux rayures et aux empreintes digitales, grâce à leurs tons plus sombres. Cette résistance accrue est bénéfique pour les médailles destinées à être manipulées au fil du temps.

Placage nickel et chrome pour une touche élégante et moderne

Finitions nickel poli et chrome: Les finitions nickel et chrome offrent une surface nette, semblable à un miroir, qui crée une esthétique moderne. Ces finitions s'accordent bien avec les designs épurés et minimalistes.

Polyvalence dans la conception des médailles: Les médailles en nickel poli ou en chrome sont souvent choisies pour les récompenses sportives et d'entreprise en raison de leur aspect moderne et élégant. Leur durabilité leur permet également d'être manipulées fréquemment.

Principaux éléments à prendre en compte lors du choix d'une finition de placage

Considérations budgétaires

Implications financières de chaque finition: Les différentes finitions ont des coûts variables, le placage d'or étant généralement plus cher que l'argent ou le nickel. Les contraintes budgétaires jouent souvent un rôle dans le choix final d'une finition.

Concilier budget et qualité: Si un aspect haut de gamme est essentiel mais que le coût est un problème, des finitions telles que l'argent ou le nickel antique peuvent donner une apparence de luxe sans le prix plus élevé de l'or.

Durabilité et résistance à l'usure

Finitions durables: Les finitions comme le nickel et le chrome offrent une résistance supérieure à l'usure, ce qui les rend idéales pour les médailles devant résister à des manipulations fréquentes, comme les médailles sportives ou les objets de collection.

Impact de la fabrication des médailles sur la longévité des finitions: Une médaille bien plaquée est une médaille qui dure. La qualité du processus de fabrication de la médaille influence directement la durabilité de la finition, c'est pourquoi il est essentiel de s'associer à un fabricant réputé.

Compatibilité avec le thème Medals Design

Aligner le placage sur l'esthétique des médailles: Chaque événement ou marque a un thème, et la finition doit le refléter. Par exemple, les finitions antiques conviennent bien aux événements à caractère historique ou patrimonial, tandis que le chrome poli est parfait pour les thèmes modernes et de haute technologie.

Utiliser le placage comme outil de marque: Les finitions de placage peuvent renforcer l'image de marque. Une entreprise prestigieuse peut préférer des médailles plaquées or, tandis qu'un événement axé sur la technologie peut opter pour des finitions chromées ou nickelées qui reflètent une ambiance moderne.

Options de finition personnalisées pour un meilleur attrait des médailles

Finitions doubles et multi-tons

Combiner les finitions pour un look unique: Le mélange de deux finitions, comme l'or et l'argent ou le mat et le brillant, crée un intérêt visuel et fait ressortir la médaille. Cette approche ajoute un élément distinctif à la conception, idéal pour des récompenses uniques et à fort impact.

Application dans les médailles finies pour les événements spéciaux: Les finitions bicolores peuvent renforcer l'attrait des médailles destinées à des événements spéciaux tels que les anniversaires d'entreprise, les compétitions sportives de haut niveau ou les commémorations, en ajoutant à leur caractère exclusif.

Finitions mates ou brillantes

Avantages des finitions mates: Les finitions mates réduisent les reflets et offrent un aspect lisse et contemporain. Elles sont pratiques pour les événements extérieurs ou les récompenses qui bénéficient d'une apparence plus discrète.

Des finitions brillantes pour un attrait éclatant: Les finitions brillantes ont un aspect très brillant qui peut rehausser l'aspect général de la médaille. La brillance est idéale pour les récompenses destinées à impressionner, ce qui en fait un choix populaire pour les médailles de cérémonie.

Ajout de textures personnalisées

Finitions gaufrées et texturées: L'ajout de textures, comme des motifs gaufrés ou gravés, apporte une couche tactile supplémentaire à la médaille. Les textures rendent les médailles plus attrayantes visuellement et plus mémorables.

Incorporation de logos et d'éléments de marque: Les textures personnalisées, telles que les logos ou les devises en relief, contribuent à renforcer la reconnaissance de la marque et à créer un impact durable. Cette caractéristique est particulièrement utile pour les médailles utilisées dans le cadre d'événements corporatifs ou promotionnels.

Assurance de la qualité dans le placage et la fabrication de médailles

Importance d'un placage de haute qualité dans la fabrication de médailles

Techniques de placage et contrôles de qualité: Les fabricants de médailles fiables effectuent des contrôles de qualité approfondis tout au long du processus de placage. Cela permet de s'assurer que chaque pièce répond aux normes de durabilité et d'apparence, et d'éviter les incohérences.

Pourquoi le placage de qualité est-il important pour les médailles personnalisées ?: Le placage de haute qualité améliore non seulement l'aspect de la médaille, mais protège également contre l'usure, les rayures et la décoloration, garantissant une finition durable qui conserve son éclat au fil du temps.

Assurer la cohérence des couleurs entre les médailles

Importance de la correspondance des couleurs: L'uniformité des couleurs est cruciale, surtout lorsqu'il s'agit de produire plusieurs médailles pour un même événement. L'uniformité des couleurs témoigne du professionnalisme et de la qualité du processus de fabrication.

Processus de fabrication des médailles pour plus de cohérence: Grâce à des techniques de production avancées, les fabricants peuvent obtenir des finitions homogènes, ce qui permet à toutes les médailles d'un lot d'avoir un aspect identique en termes de teinte et de polissage.

Comment choisir le bon partenaire de placage pour vos médailles personnalisées ?

Recherchez une expérience dans la fabrication de médailles

Avantages du choix d'un fabricant expérimenté: Les fabricants expérimentés possèdent le savoir-faire nécessaire pour fournir un placage de qualité. Leur connaissance des différentes finitions et techniques leur permet de répondre à des normes élevées.

Certifications et normes de qualité: Un fabricant possédant des certifications reconnues garantit des pratiques de fabrication de médailles fiables et de haute qualité. Les normes industrielles garantissent la qualité du placage et du processus de production.

Évaluer les options de personnalisation

Variété de finitions proposées: Une large gamme de finitions disponibles démontre la polyvalence du fabricant, vous offrant plus d'options pour correspondre au style de votre événement.

Flexibilité pour les demandes spéciales de conception de médailles: Si votre projet nécessite des finitions uniques, comme un placage bicolore ou texturé, un fabricant ayant des capacités de personnalisation peut répondre à ces demandes et fournir une médaille finie vraiment unique en son genre.

Conclusion

Le choix de la finition idéale pour les médailles personnalisées implique un mélange d'esthétique, de durabilité et d'alignement avec les objectifs de l'événement. En comprenant les différentes options de finition, en tenant compte de facteurs tels que le budget, la durabilité et le design, et en choisissant un fabricant expérimenté, vous pouvez vous assurer que vos médailles personnalisées laisseront une impression mémorable et durable. La bonne finition transforme une simple médaille en un souvenir précieux, symbole de réussite et de prestige. Le fait de travailler avec un fabricant axé sur la qualité améliore encore le résultat, faisant de vos médailles un hommage durable à l'excellence.